FMLab can look after the design of components with a high technical content in polymeric material and assess their feasibility in most challenging projects.

To take full advantage of the possibilities offered by plastic materials and their processing technologies, it is necessary to design the componentsaccording to rules that differ from those of the conventional mechanics.

It is necessary to bear in mind the properties’ materials and the impact of the component geometry on the execution of the mold and on the molding.

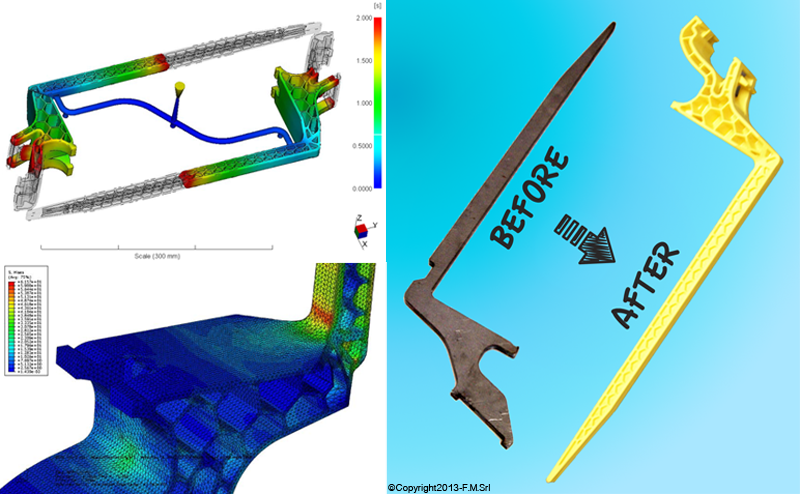

Metal Replacement

It is possible both to create new components, designed from the very beginning in plastic material, and also to reconvert components in metal alloy: this practice is called Metal Replacement.

The use of plastics may involve a long list of benefits including:

- Possibility to manufacture structural components able to combine high mechanical strength to a reduced mass;

- Possibility to produce components with complex shapes and designs;

- Low price, high productivity and reduction of lead time;

- Possibility of merging different components reducing the bill of materials and therefore the complexity of products (and even their management);

- Possibility to choose between a virtually infinite range of colors and surface treatments;

- Removal of corrosion problems and possibility to produce components with high resistance to wear;

- Reduction of noise and vibration;

- Possibility of producing plastic components endowed with electrical conductivity and / or thermal plus (useful for example in the electrical / electronicfield );

- Reduced environmental impact thanks to lower energy used in the design process and the use of bio-based polymers.

In recent years high-performance polymeric materials have been developed: they have allowed to replace metals in more and more loaded applications.

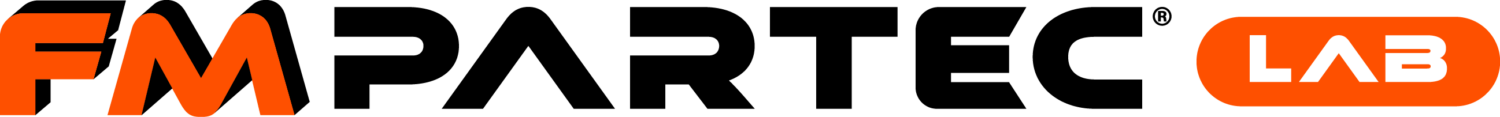

Today you can also use product simulations (structural FEM) and process simulation (injection molding) to achieve better and cheaper products.

In particular, the structural FEM allows to predict the efforts which will undergo the article and review its geometry in this direction, whilemolding simulation allows to predict the critical aspects of the production process thus changing the mold.